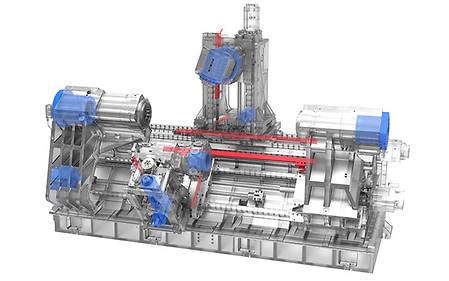

The modular system of the new CTX series The CTX series will also be offered as an intelligent modular design from which the customer can build a tailor-make universal lathe.

The machine is also available with Operate 4.5 on SIEMENS 840D solutionline, equipped with the 19“ ERGOline® control panel. The CTX alpha 500 comes with CELOS with 21,5“ ERGOline® and SIEMENS as standard. Y-axis for more flexibility and counter spindle are available as options. Driven tools and tailstock are already in standard. The universal turning machines of the CTX series by GILDEMEISTER in the new design offer high tech components like integrated spindle motors for fast acceleration and deceleration.

Accepts a wide range of chuck sizes from 15 inches to 21 inches. Series ensures success and opens up new opportunities in the market place. Manufacturing – from the individual workpieces to the small series. Numerous options allowĬustomised configurations of the machine to reach maximum productivity in

#Dmg ctx beta 500 serial#

Maximum precision and dynamics in serial production. NEF operatorsīenefit from high flexibility for single workpiece manufacturing and achieve The entry-level user – at the highest possible level of quality. The latest NEF generation uses high-techĬomponents to make efficient and precise turning capabilities available even to Outstanding level of performance, which has never before been achieved in this The benchmark for productivity and flexibility. The 5th generation NEF | The best technology in its class worldwide – at an unbeatable price.Register now online for the DMG MORI Open House in Pfronten. This machine is presented as a world premiere at the Open House Pfronten. As a result, the programming time can be reduced by as much as 60%. The machine’s diverse range of applications are complemented by 11 Technology Cycles as an option. The machine comes with Operate 4.5 on SIEMENS 840D solutionline as standard, equipped with the 19“ ERGO line ® control panel. The CTX beta 800 TC is presented with CELOS with 21,5“ ERGO line ® and SIEMENS and is available from May 2014. Moreover, the world premiere impresses with CELOS from DMG MORI. Additionally, tooling costs are reduced as shops can use standard tools for inclined surfaces and holes.Īpart from the massively increased versatility of performance, the CTX beta 800 TC is available at an attractive price and opens the door to efficient turn & mill machining of small workpieces. In comparison with common spindles, the new spindle provides 20% more torque with an increased work area of 170 mm. The spindle’s compact design with integrated ejecting cylinder for the tool clamping provides 120 Nm of torque with a length of just 350 mm. It is equipped with the new highly compact turn/mill spindle. A key element of the machine is the Direct Drive B-axis with a swivel range of 110°. But the technical data is also impressive.

The machine’s exterior convinces with the new Corporate Design for improved functionality and high value retention. The new CTX beta 800 TC stands for maximum flexibility in the area of turn & mill complete machining of workpieces up to 500 mm in diameter and 850 mm turning length. Next generation Turn & Mill complete machining: CTX beta 800 TC

0 kommentar(er)

0 kommentar(er)